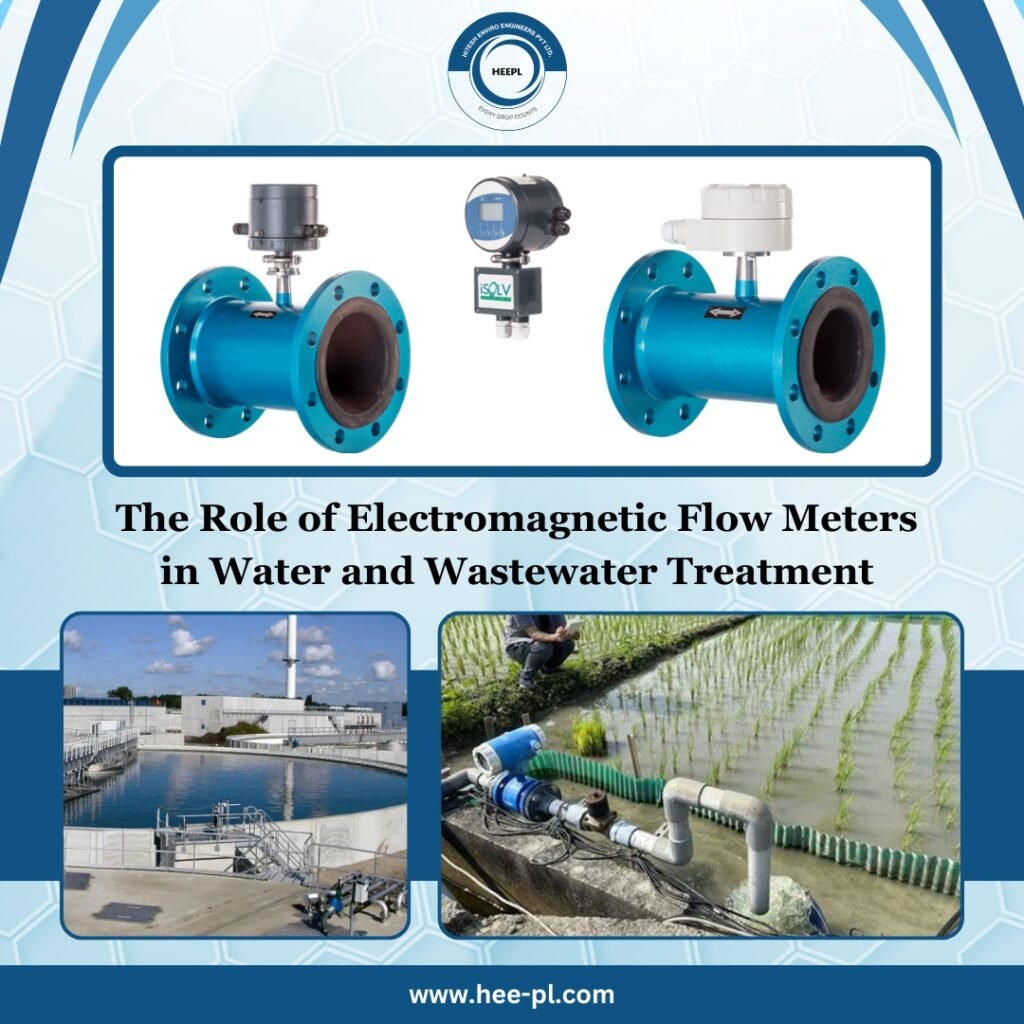

Water and wastewater treatment facilities rely on accurate flow measurement to ensure efficiency, regulatory compliance, and cost-effectiveness. Among various flow measurement technologies, electromagnetic flow meters (mag meters) play a crucial role due to their high precision, reliability, and suitability for conductive liquids. This blog explores the importance of electromagnetic flow meters in water and wastewater treatment, their working principles, benefits, and applications.

How Electromagnetic Flow Meters Work

Electromagnetic flow meters operate based on Faraday’s Law of Electromagnetic Induction, which states that a voltage is induced when a conductive fluid moves through a magnetic field. The key components of a mag meter include:

- Electrodes: Detect the induced voltage proportional to the fluid velocity.

- Magnetic Coils: Generate the magnetic field required for induction.

- Flow Tube: The section where fluid passes and interacts with the magnetic field.

- Transmitter: Converts the detected voltage into flow rate measurements.

Since electromagnetic flow meters do not contain moving parts, they experience minimal wear and tear, making them highly durable and low maintenance.

Benefits of Electromagnetic Flow Meters in Water and Wastewater Treatment

- High Accuracy: Provides precise flow measurements, typically with an accuracy of ±0.5% or better.

- No Moving Parts: Reduces mechanical wear and maintenance costs.

- Minimal Pressure Drop: Ensures energy efficiency and uninterrupted flow.

- Wide Range of Applications: Suitable for clean water, wastewater, and sludges with high solids content.

- Chemical Compatibility: Works effectively with corrosive and abrasive liquids due to non-reactive linings like PTFE or rubber.

- Scalability: Available in various sizes to handle small to large pipeline diameters.

- Bi-Directional Flow Measurement: Allows measurement in both forward and reverse directions.

Applications in Water and Wastewater Treatment

- Municipal Water Supply

- Wastewater Treatment Plants

- Industrial Effluent Monitoring

- Irrigation Systems

- Desalination Plants

Choosing the Right Electromagnetic Flow Meter

- Selecting the appropriate mag meter depends on factors such as:

- Pipeline Size: Choosing the correct diameter for optimal accuracy.

- Fluid Conductivity: Ensuring the liquid meets the minimum conductivity requirement (~5 µS/cm).

- Lining Material: Selecting compatible materials based on fluid type (e.g., rubber for sludge, PTFE for corrosive liquids).

- Installation Environment: Considering factors like temperature, pressure, and potential for sediment buildup.

Conclusion

Electromagnetic flow meters are indispensable in water and wastewater treatment due to their accuracy, durability, and ability to handle challenging flow conditions. As global water management continues to prioritize efficiency and sustainability, mag meters will remain a vital tool in ensuring effective resource utilization and environmental protection.

By implementing high-quality electromagnetic flow meters, water treatment facilities can enhance operational efficiency, reduce costs, and maintain compliance with regulatory standards.