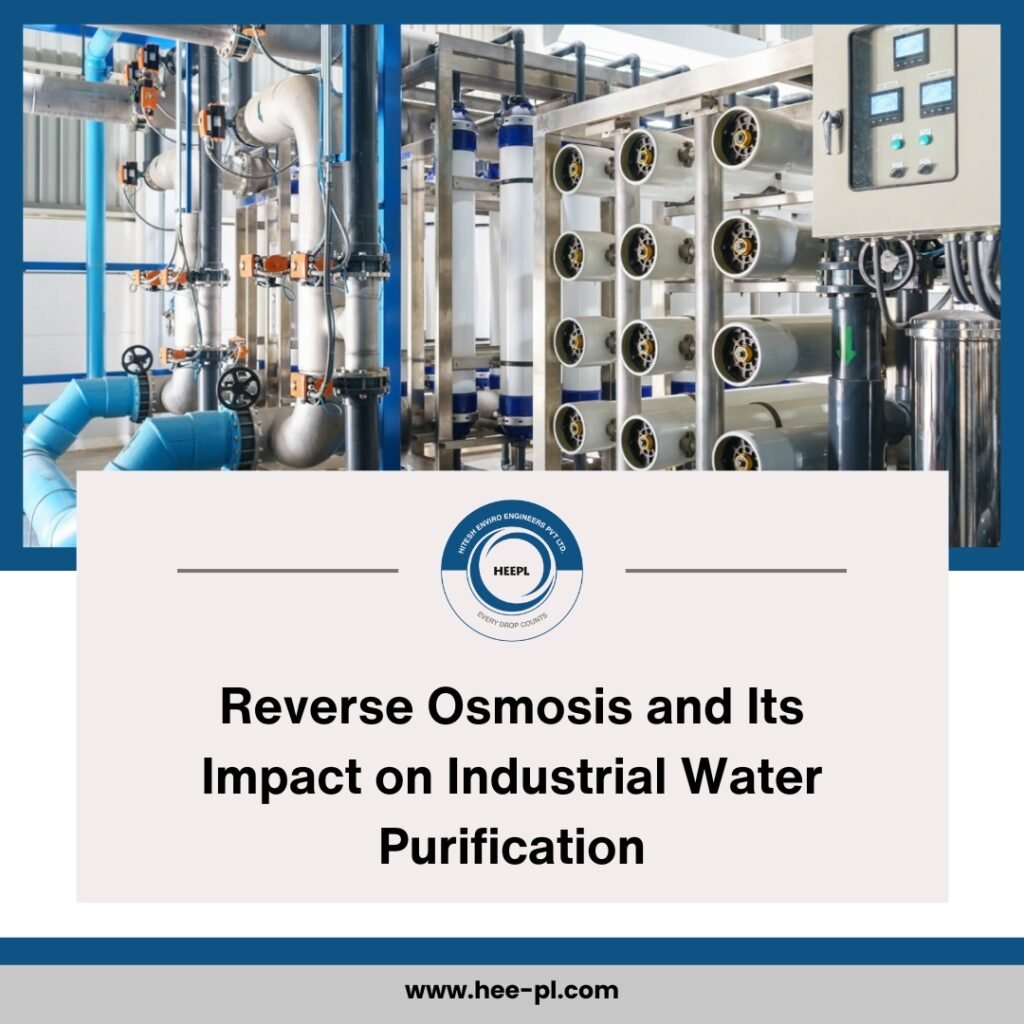

Water is a vital resource in industrial operations, used extensively in manufacturing, processing, and maintenance. However, not all water is suitable for industrial applications due to the presence of contaminants, minerals, and other impurities. Ensuring water purity is essential for efficiency, equipment longevity, and regulatory compliance. One of the most effective solutions for industrial water treatment is Reverse Osmosis (RO), a technology that has transformed water purification across multiple industries.

In this blog, we’ll delve into the workings of Reverse Osmosis, its benefits, challenges, and why it has become an indispensable solution for industrial water purification.

In an era where sustainable resource management is becoming a global priority, industries are under increasing pressure to optimize their water usage. Advanced technologies like flow meters equipped with telemetry offer a powerful solution to monitor, analyze, and reduce water consumption effectively. Here’s how these smart systems can revolutionize water management for industries.

What is Reverse Osmosis?

Reverse Osmosis is a filtration process that removes dissolved solids, contaminants, and other impurities by forcing water through a semi-permeable membrane under high pressure. The membrane only allows pure water molecules to pass through, while larger particles, salts, and pollutants are left behind and flushed out as waste. The result is high-quality purified water that meets industrial standards.

The Role of Reverse Osmosis in Industries

Industries require water that is free from harmful substances to prevent damage to machinery, ensure product quality, and comply with strict regulatory standards. RO systems are widely used across several sectors, including:

- Manufacturing: Prevents scale buildup and contamination in equipment, ensuring smooth operations.

- Pharmaceuticals: Produces ultrapure water essential for drug formulation and medical applications.

- Food and Beverage: Maintains hygiene, improves product taste, and ensures food safety.

- Power Generation: Reduces scaling and corrosion in boilers and turbines, enhancing efficiency.

- Electronics and Semiconductor Manufacturing: Ensures impurity-free water critical for circuit fabrication and production.

Key Benefits of Reverse Osmosis in Industrial Applications

- Exceptional Water Purity: RO removes up to 99% of dissolved solids, bacteria, and contaminants, producing high-quality water.

- Cost-Effective Solution: Compared to traditional water treatment methods, RO minimizes the need for chemical treatments and reduces maintenance costs.

- Eco-Friendly Technology: RO reduces wastewater discharge and lowers reliance on chemicals, contributing to sustainable industrial practices.

- Enhanced Equipment Longevity: By preventing scale formation and corrosion, RO extends the lifespan of industrial machinery and equipment.

- Regulatory Compliance: Many industries must adhere to stringent water quality regulations, and RO ensures compliance with minimal effort.

Challenges of Implementing Reverse Osmosis in Industries

Despite its many advantages, Reverse Osmosis systems come with challenges that must be addressed for optimal performance:

- Pre-Treatment Requirements: Proper pre-filtration is necessary to prevent membrane fouling and extend system longevity.

- Energy Consumption: RO systems operate under high pressure, which can lead to increased energy costs. Energy-efficient designs help mitigate this challenge.

- Wastewater Disposal: The reject water containing concentrated contaminants must be managed responsibly to minimize environmental impact.

Best Practices for Industrial RO Systems

To maximize the efficiency and longevity of an RO system, industries should consider the following best practices:

- Regular Maintenance: Routine checks and cleaning of membranes to prevent fouling and maintain optimal performance.

- Water Quality Testing: Continuous monitoring to ensure water meets required purity standards.

- Energy Optimization: Utilizing energy-efficient pumps and recovery systems to reduce operational costs.

- Proper Waste Management: Implementing strategies to recycle or treat RO reject water to minimize environmental impact.

Conclusion

Reverse Osmosis has become a game-changer in industrial water purification, offering a reliable, cost-effective, and environmentally sustainable solution. As industries increasingly focus on efficiency, sustainability, and regulatory compliance, the adoption of RO technology continues to grow. Investing in a well-designed and well-maintained RO system ensures high-quality water supply, improved productivity, and long-term cost savings.

By leveraging the power of Reverse Osmosis, industries can enhance their operations while reducing their environmental footprint, making it a crucial component of modern water treatment strategies.